Discover

Design and Development

A full time team of professionals, for whom creating is a passion rather than a job, is responsible for the design and development of our products.

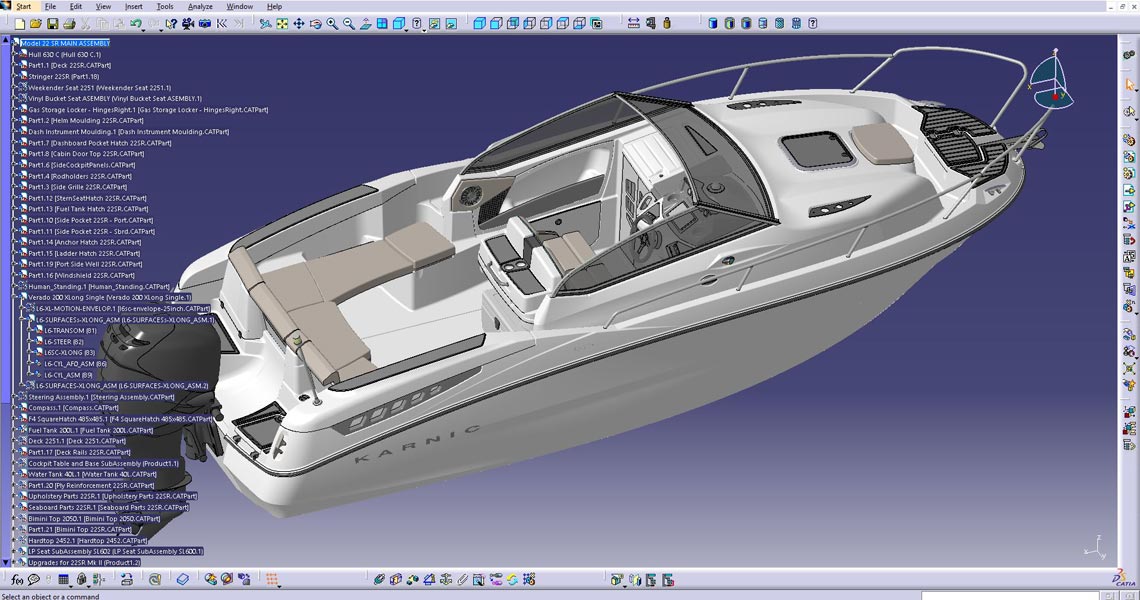

What is eventually seen as an attractive shiny product in a showroom has started from a concept sketch on blank paper, analysed and refined, optimised and then modelled in three dimensions on the computer. Advanced CAD software enables our design team to build the 3D models to the finest detail, visualise the shapes, check practicality and then finalise the design.

In all our designs we pay high emphasis in giving value to our products. We always aim for flexible multi-purpose designs rather than limiting to just one specific use. We achieve this by dedicating time to study and analyse before finalising.

Our technology enables us to develop complex attractive shapes and practical layouts, give unique style with no limitations, design for optimal structural integrity but also optimise processes in the production for minimum assembly times. Fuel tanks, for example take only minutes to install because self locking shapes have been designed into the all composite stringer system of our boats.

Converting the digital 3D models to real physical shapes becomes the next chapter where an in-house 5-axis robotic milling machine is used to produce the physical models to an accuracy of a fraction of a millimetre. These subsequently evolve through different phases of finishing to finally end-up as a complete set of negative tooling for all components of the boat model in our production.

Once tooling is completed, last stage in the development of a new model is the making of a prototype that is extensively tested in various conditions and if necessary refined, before it is finally approved for production. To such extend we test that the prototype boat is refined to a level that is identical to all production boats that follow.